The 2018 IRC/IECC requires a continuously operating mechanical ventilation system to remove stale air and add fresh air to each dwelling.

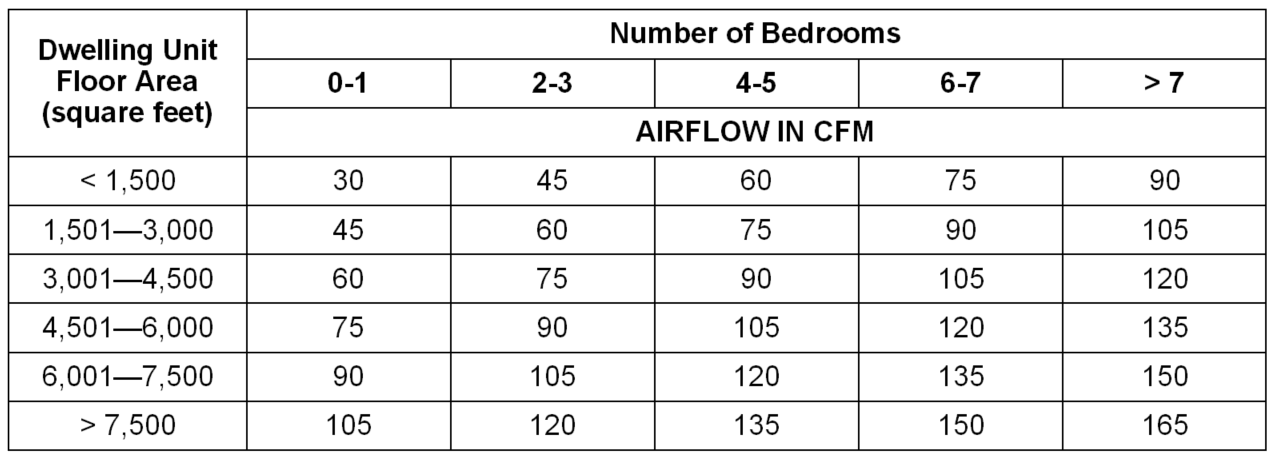

The required system flow rates are specified in Section M1505 of the 2018 IRC:

"Continuous operation" requires the system to either run at all times or cycle on at least once every four hours at a rate adequate to provide an overall average rate that meets the minimum flow requirement in the table.

The system must be equipped a manual override.

Since the fan will run continuously, it must meet efficiency requirements that depend on the system design and size:

Mechanical ventilation system designs typically fall into one of three categories:

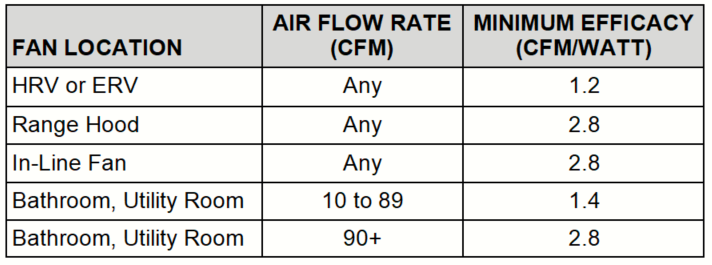

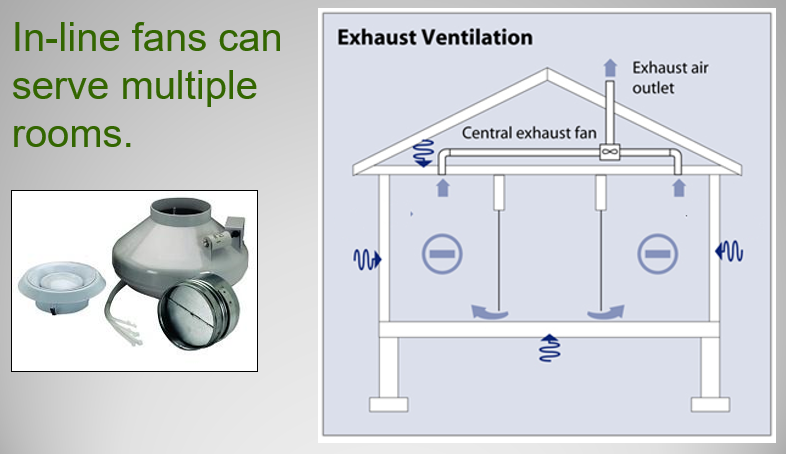

Exhaust only systems use one or more fans to remove stale air. This depressurizes the building, so fresh air enters through leaks in the envelope. These can be local fans that pull air out of a single space or they can be fans that draw from multiple spaces.

Exhaust only ventilation systems are the most common design. This strategy is usually accomplished with a bath fan, which then serves as both local exhaust and whole-building ventilation.

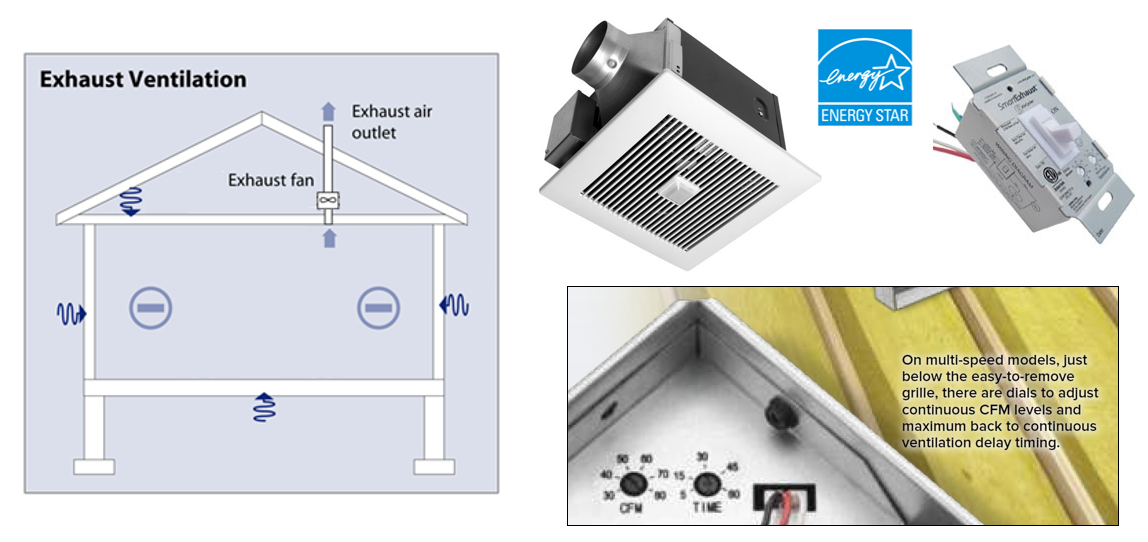

The selected bath fans often have a higher flow rate than is required by the table, since they need to provide high flow for local exhaust (when an occupant is using the shower) and lower flow for whole building exhaust. The low flow can be accomplished by a control system that either cycles the fan on/off regularly or turns down the speed of the fan. Some fans are available with integral ventilation controls. With other fans, an external controller/timer must be installed.

This ventilation method is the most affordable option, but it has a few drawbacks. One is the energy penalty associated with removing conditioned air and bringing in unconditioned air. Another is that fresh air that enters may introduce unwanted moisture into building cavities, especially in warm humid climates. And the last is that it ventilates the spaces around that bathroom very well, but it doesn’t ventilate rooms that are far away very effectively.

One way to improve the effectiveness of exhaust-only systems is to use multiple fans in different locations of the house. They can be set up so the total flow rate meets the calculated ventilation requirement. Of course, this setup is about twice as expensive to install. Another way to accomplish the same goal is to install an inline fan with multiple inlets to draw air from multiple locations in the house.

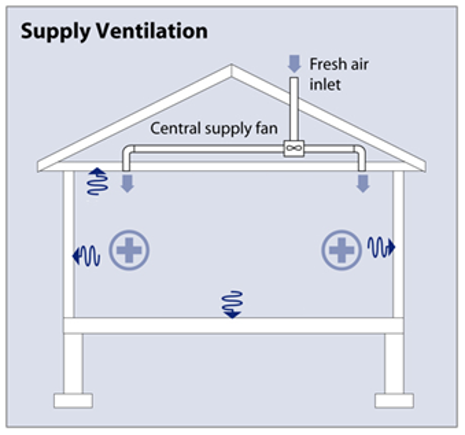

Supply only systems use one or more fans to push fresh air into the building. They pressurize the building so stale air is pushed out through leaks in the envelope. This could be done with a wall or attic mounted fan. But there are some issues with this approach. One is that house air is pushed into building cavities where it might cause moisture problems, especially in cold climates. The other is that in the winter, cold outdoor air is introduced into just a few locations where it is likely to cause comfort issues. So this approach is rarely used.

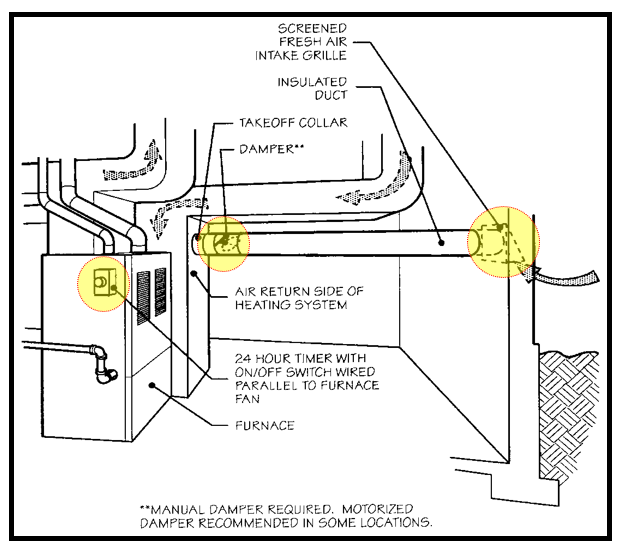

A more commonly used approach to supply-only ventilation is the addition of an outdoor air intake to the return stream of a ducted system. A drawing of a typical arrangement is shown below.

This design has several advantages:

These systems are very common in commercial buildings, but they are also installed in some houses. One drawback to them is that if the design only includes a fresh air intake duct, the only time fresh air is introduced is when heating and cooling is needed.

For the system to work properly, the air handler fan must cycle on and off regularly, 365 days a year. An optimal system includes a motorized damper to open the intake only when needed. The duct should be sized to get the just the right amount of air flow, and there should be a controller that turns the system off and on regularly. Many air handler/furnace manufacturers offer kits and controls to accomplish these goals.

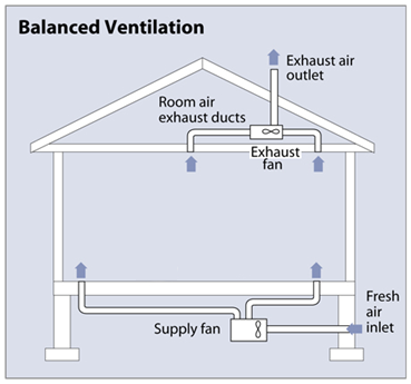

Balanced systems use a balanced combination of fan-driven supply and exhaust air. The supply fans bring in the same amount of air that the exhaust fans pull out, so no pressures are created in the house by them.

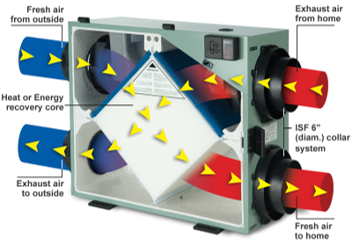

This can be done with separately installed fans, but when there are two air streams, the opportunity exists to move heat and moisture from one stream into the other, improving energy use and comfort. Therefore, balanced ventilation is typically done with a pre-designed, all-in-one, system. This diagram shows how it works. We call the devices HRV’s and ERV’s: heat recovery ventilators and energy recovery ventilators.

The fresh air enters on one side and the exhaust air exits on the other. A heat exchanger separates the streams so they don’t mix, but it allows heat to move from one stream to the other.

If the heat exchanger is made of metal or plastic, we call the device a Heat Recovery Ventilator, or HRV. It only transfers heat through it. But if the heat exchanger is made of a material that wicks water, like dense paper, it will transfer moisture in addition to heat. We call these devices Energy Recover Ventilators, or ERV's. They significantly improve performance by drying out the incoming air on humid summer days, or adding moisture to the incoming air on a cold winter days.

For these reasons, balanced ventilation is the most preferable option, but it is also the most expensive and complicated to install.